Price 150000.0 आईएनआर/ टुकड़ा

Specification

- प्रॉडक्ट टाइप

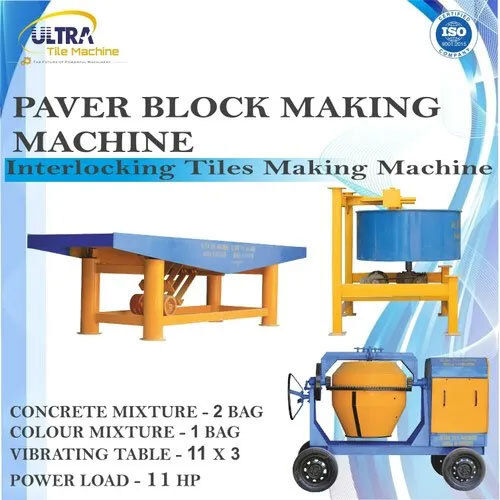

- Interlocking Paver Block Making Plant

- सामान्य उपयोग

- Construction

- तरीका

- प्रोसेसिंग

- पावर

- हार्सपावर (HP)

- वोल्टेज

- वोल्ट (v)

- वारंटी

- 1 Year

- ईंट का कच्चा माल

- टाइप करें

- आयाम (एल* डब्ल्यू* एच)

- मिलीमीटर (mm)

- रंग

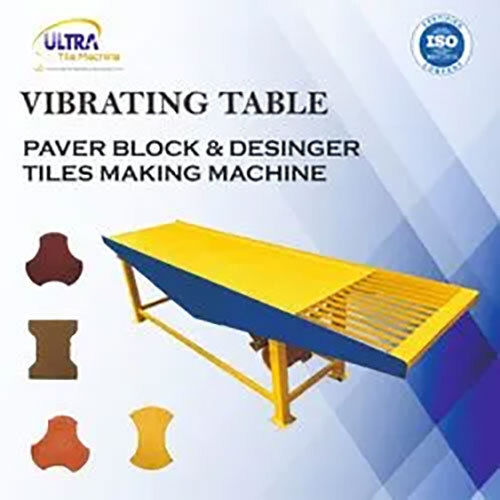

- Yellow And Blue

Trade Information

- Minimum Order Quantity

- 1 टुकड़ा

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- दिन

- मुख्य घरेलू बाज़ार

About

We are manufacturer, exporter and supplier of high-qualityMild Steel Paver Block Making Vibrating Machine, Vibrating Table, PAVER BLOCK VIBRATING TABLE, Concrete Paver Block Vibrating Table, Cement Brick & Paver Block Making Machine, Automatic Block Making Machine, Automatic Cement Brick Making Machine, Automatic Hydraulic Fly Ash Brick Making Machine, Colour Pan Mixture, Hydraulic Concrete Block Making Machine, Concrete Paving Block Making Machine, Fly Ash Brick Making Machine, Sumi Automatic Brick Making Machine, Paver Blocks Making Machine,from uttam nagar, India.

We are manufacturer, exporter and supplier of high-qualityMild Steel Paver Block Making Vibrating Machine, Vibrating Table, PAVER BLOCK VIBRATING TABLE, Concrete Paver Block Vibrating Table, Cement Brick & Paver Block Making Machine, Automatic Block Making Machine, Automatic Cement Brick Making Machine, Automatic Hydraulic Fly Ash Brick Making Machine, Colour Pan Mixture, Hydraulic Concrete Block Making Machine, Concrete Paving Block Making Machine, Fly Ash Brick Making Machine, Sumi Automatic Brick Making Machine, Paver Blocks Making Machine,to various cities including Mumbai, Pune, Bangalore, Jaipur, Kanpur, Lucknow, Noida, Patna, Ranchi, Hyderabad, Imphal, Guwahati, Kolkatta, Assam, Itanagar, Gangtok, Jammu, Kashmir, Srinagar,West Bengal,Varanasi,Meerut,Ghaziabad,Jharkhand,Madhya Pradesh,Prayagraj,Kanpur, Gurgaon, faridabad, Bhiwani, Bhiwandi, Uttarakhand.

Efficient Brick Production for Construction Needs

This plant is engineered to produce high-quality interlocking paver blocks at a rapid pace, yielding up to 3000 blocks in a standard 8-hour shift. Its versatile mould system accommodates customized shapes to suit specific project requirements, making it ideal for diverse construction applications.

Advanced Automation and User-Friendly Controls

Managed by a PLC-based control panel, the plants semi-automatic and fully automatic modes offer flexibility in operation. Material feeding is completely automated through a hopper, and the process is streamlined for minimal workforce involvement, typically requiring only 2-4 operators.

Durability, Safety, and Quiet Operation

Built with a robust hydraulic/vibration mechanism, the plant minimizes operational noise (under 80 dB) and assures user safety. Its sturdy frame, spacious pallet size, and large oil tank deliver consistent performance even under demanding conditions, all covered by a 1-year manufacturer warranty.

FAQs of Interlocking Paver Block Making Plant:

Q: How does the Interlocking Paver Block Making Plant operate?

A: The plant utilizes hydraulic pressure and vibration methods, combined with a PLC-based control system. Blocks are produced within a 20-30 second cycle, with raw materials automatically fed via the hopper, and operation can be managed in manual or automatic modes.Q: What materials can be used as raw inputs for paver block production?

A: The plant efficiently processes cement, sand, stone dust, fly ash, slag, and similar mineral additives, allowing flexibility in block composition and strength for various construction needs.Q: When can customized block shapes be implemented in the manufacturing process?

A: Customized interlocking moulds can be installed prior to production. The plant supports a range of block heights and shapes, so specific designs should be provided during setup to ensure precise output.Q: Where is the Interlocking Paver Block Making Plant typically supplied and used?

A: Manufactured and supplied in India, this machine is ideal for construction companies, real estate developers, and contractors needing reliable paver block production on-site or at dedicated manufacturing facilities.Q: What steps are involved in the block-making process with this plant?

A: The process includes material loading (via automatic hopper), mould selection and placement, hydraulic pressing and vibration, block formation (within 20-30 seconds), and block extraction. The control system coordinates each stage for consistency and efficiency.Q: How many operators are required for optimal machine operation?

A: The plant is designed for efficiency, typically requiring only 2 to 4 workers to manage production tasks, machine oversight, and block handling, thanks to its automated features.Q: What advantages does this paver block plant offer over conventional brick-making systems?

A: It offers rapid cycle times, customizable shapes, lower noise levels, reduced manpower needs, and consistent block quality. The automatic feeding, flexible operation modes, and robust build make it a cost-effective and versatile solution for modern construction projects.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in पेवर ब्लॉक बनाने की मशीन Category

GST : 09IBSPK6096P2Z7

|

ULTRA TILE MACHINE

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |

जांच भेजें

जांच भेजें